Muscat: Oman’s next generation of businessmen and engineers now have the most up-to-date skills to pursue their careers, after an intensive 3D printing course that taught them the value and importance of such cutting-edge technology.

Sponsored by BP Oman as part of its social investment programme, the course saw Seeb-based fabrication company InnoTech conduct two workshops, which saw more than 100 participants in total, thereby inspiring students and jobseekers to understand alternative methods of manufacture, and how they could benefit the Sultanate in future.

These courses were held at the Nizwa Cultural Centre and the Ibri College of Technology, where participants spent four days of practical training in 3D design, 3D printing and digital fabrication skills as part of a technique known as additive manufacturing

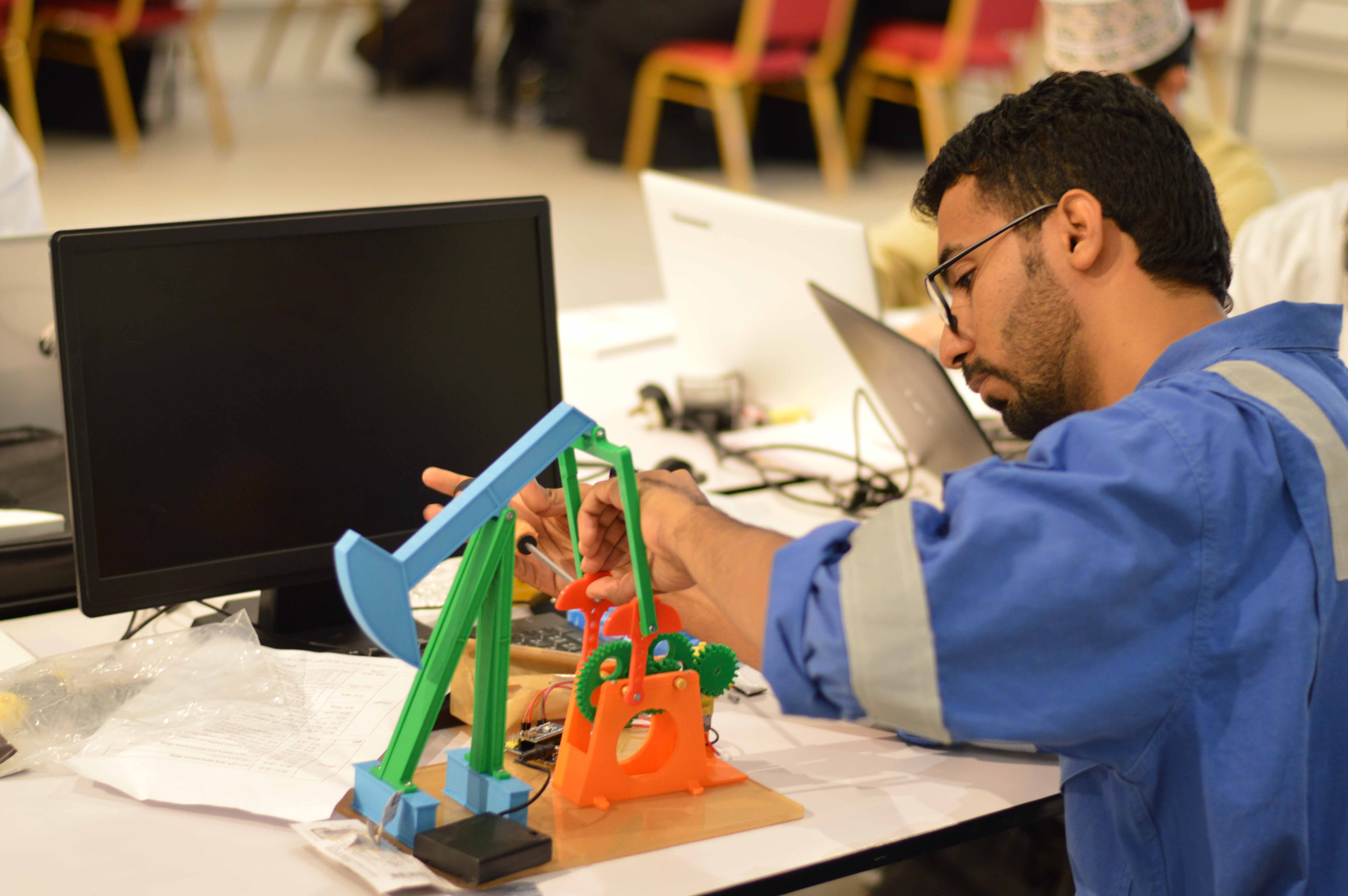

On the first day, participants learned how to design 3D Computer Aided Design (CAD) software, which is used to increase designer productivity, improve design quality, and create a manufacturing database. The following day, they absorbed the use of more complicated design tools and later a competition was held where participants vied to build the highest tower using some of the tools to simulate how 3D printers work. The final day concluded with teams assembling parts of the 3D printer and building their final project.

“Nowadays, this technology can be seen in every major industry worldwide from automotive, aerospace, defence and consumer products to medical supplies,” said Othman Al Mandhari, the co-founder and CEO of InnoTech. “Additive Manufacturing is important in the rapid prototyping and manufacturing industry for many reasons, mainly for its ability to create simple product designs and significantly reduce weight of parts.

“This technology is further supporting innovation and creativity through allowing users to try different iterations without bearing additional cost, unlike conventional manufacturing,” he added. “Supporting our ambition to instil a culture of additive manufacturing, 3D printers will be permanently installed in the Nizwa Cultural Center and Ibri College of Technology. Students and staff will be able to use them for free at any time.”

Shamsa Ahmed Al Rawahi, BP Oman’s social investment programme officer, added: “Digital fabrication processes and technologies are becoming an essential part of the modern product manufacturing and therefore we wanted to present this notion to young Omanis. Through harnessing innovation and research skills, BP’s Social Investment Programme delivers academic initiatives as well as practical and experiential components to the people.”

Four trainees will be chosen for a two-month internship in InnoTech and a possible job opportunity after the internship. InnoTech is an Omani company founded in 2013 by three young Omani engineers. They provide prototyping and manufacturing solutions in Oman and aim to help local inventors and entrepreneurs to make their ideas into prototypes and then products. InnoTech also offers virtual reality applications and educational courses in 3D printing, programming and 3D designing.